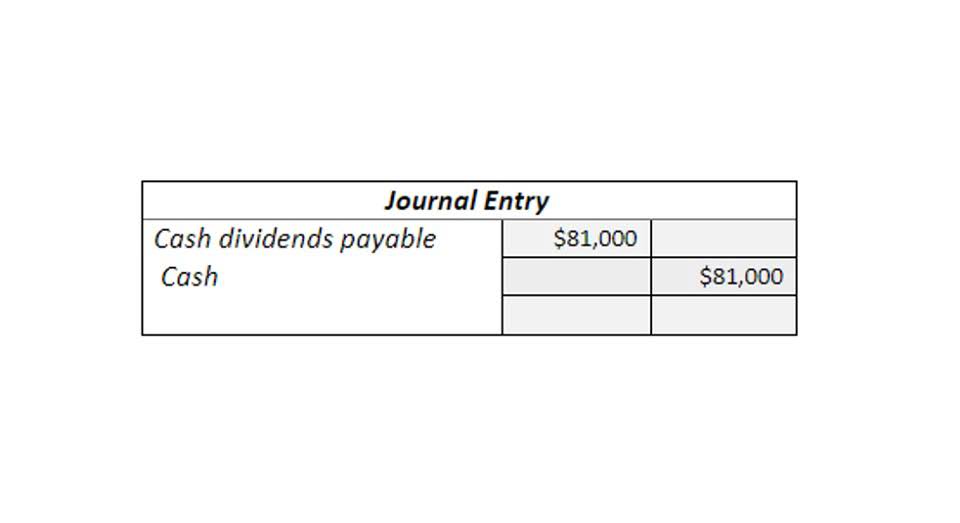

This is one of the main problems with calculating in reorder point calculator Excel spreadsheets. Someone has to export up-to-date data before the reorder point can be calculated. This is a retained earnings step that will likely be overlooked when the warehouse is busy and, of course, busy periods are when businesses need inventory oversight the most. The second formula variant simplifies the calculation by focusing directly on Lead Time Demand.

How to manage the Reorder Point in manufacturing companies?

Many business owners and managers view ROP as a somewhat mystical figure, hard to pinpoint accurately, potentially leading to either overstocking or understocking. This ambiguity arises from the challenges in accurately predicting market demand and supply chain inconsistencies. Implementing effective Reorder Point strategies is essential for optimising inventory management.

The Mechanics of Calculating Reorder Point

A well-calculated ROP minimises inventory management costs by reducing holding expenses and avoiding costly stockouts. It plays a key role in maintaining customer satisfaction by ensuring products are available when needed, thereby preventing lost sales and customer defection. For operational continuity, particularly in manufacturing, an effective ROP prevents disruptions caused by running out of materials or goods. Additionally, regularly adjusting ROP based on actual sales data improves demand forecasting and inventory planning. Lastly, optimising ROP contributes to better cash flow management by freeing up capital from excess stock, allowing businesses to invest in other critical areas.

- By having a clear understanding of the reorder point, businesses can better manage their inventory levels and improve overall efficiency.

- In this case, we’re going to assume that our SLA is 15 days instead of 5.

- In other words, each time your stock hits 50 keyboards, you would send a purchase order to your keyboards supplier.

- For businesses, it is crucial to know when to order extra inventory to avoid issues like overstocking and understocking.

- Historical data is crucial to calculating the standard deviation of lead time.

- The daily sales velocity, or the average number of units you sell per day, differs for everything you sell.

- It is calculated based on the expected usage rate, lead time for receiving new inventory, and safety stock, and it is used to trigger a reorder when the inventory level drops to or below the ROP.

Final thoughts on the reorder point and its importance in inventory management

On the flip side, maintaining excess inventory ties up capital and incurs additional holding costs. By setting the ROP at an optimal level, businesses can strike a balance between avoiding stockouts and minimizing excess inventory, leading to cost savings. By setting an appropriate ROP, businesses can avoid stockouts, which can result in lost sales, dissatisfied customers, and damaged reputation. Reaching the reorder point triggers the replenishment process, ensuring that stock is available before it depletes. For ecommerce businesses with more than a handful of products, there are countless calculators, many of which come with automated inventory management systems. The software can streamline your reordering processes among a lot of other operational tools.

Sage makes no representations or warranties of any kind, express or implied, about the completeness or accuracy of this article and what does rop mean in business related content. This long-term view is vital to account for seasonal variations and other fluctuating factors that can affect your sales volume. Read up on contemporary strategies to transform your Demand Planning process. ○ Analyse past orders to determine the average time from order placement to receipt.

Automated solutions simplify managing reorder points by making calculations based on real-time data – ensuring you’re always one step ahead. In essence, these case studies underscore the immense value that comes with mastering your reorder points as part of your overall business strategy. Precise calculation and regular review of ROPs have proven to be key factors contributing to operational efficiency, which directly translates into positive growth trajectories. A harmonious balance between stocking enough items to meet consumers’ needs without unnecessarily tying up capital in excess stock. Remember, an accurate calculation helps anticipate variability—a key step towards preventing out-of-stock situations. Multi-warehouse operations face many inventory management challenges, especially when managing storage and order…

Economic Order Quantity (EOQ) in Inventory Management

Nowhere does a third party have a more significant impact than within your supply chain. The values used to calculate your reorder point and date are fully customizable for each SKU. You can even adjust how far back the system looks to calculate your sales velocity, allowing you to adjust for any potential seasonality or outlier sales. If you are a small startup, you might be using Excel for inventory management, and calculating reorder points. For Supplier B, your reorder point will be higher because you need to account for more stock days between your order and when new stock arrives.

It’s calculated based on your sales patterns and delivery timeframes to ensure a seamless supply chain and efficient delivery to your customers. ○ Use statistical methods or simpler rules of thumb to set safety stock levels. Understanding and optimizing the reorder point is not just a theoretical exercise but a practical necessity for businesses aiming to streamline their operations and maintain a responsive supply chain.

What is the purpose of a reorder point?

Next, a reorder point must consider a supplier’s lead time or the amount of time it takes for an ordered shipment to arrive. By understanding and implementing the ROP effectively, you can streamline your operations, enhance customer satisfaction, and maintain a competitive edge in your market. Unpredictable changes in the supply chain, such as delays or disruptions, can impact the effectiveness of your ROP strategy. With a well-managed inventory, you ensure that popular items are always available, thereby increasing customer satisfaction and loyalty. Moreover, this precise timing helps maintain a lean inventory, reducing unnecessary storage costs and minimizing the risk of inventory obsolescence.

Calculating Your Buffer Stock

Next, they review their order history Bookkeeping for Startups with the publisher and determine that it consistently takes 7 days from placing an order to the books arriving and being shelved. Choosing the ideal reorder point ensures that your business does not dip below its safety stock level. Taking the delivery time into account, an ideal reorder point would be above your safety stock level. While businesses have an official lead time from suppliers in their service level agreements, the exact number can vary from time to time. If their SLA says 5 days, they more often than not deliver within 2 days.